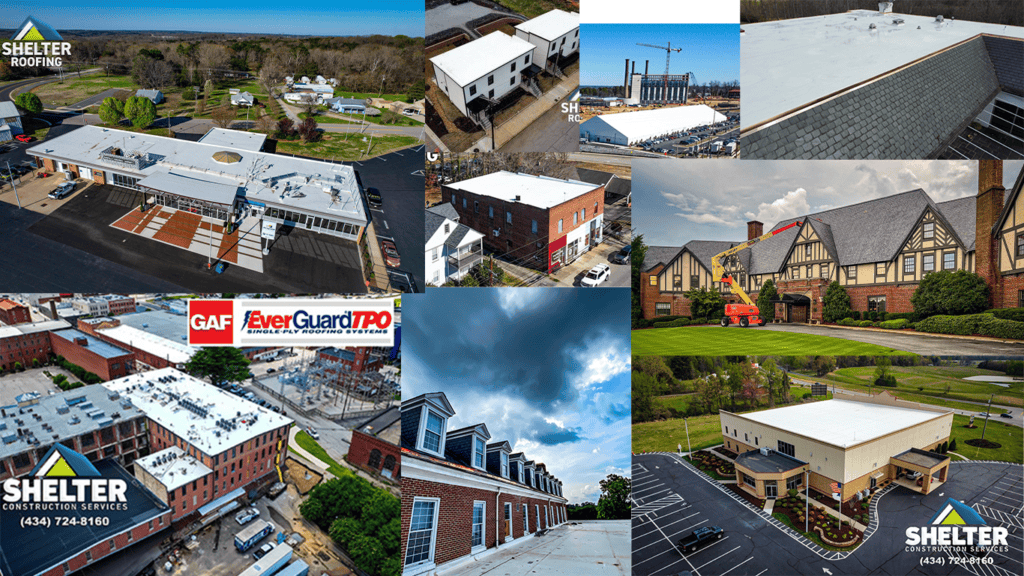

Commercial Roof Contractor Shelter Construction Services

The cost of commercial roofing labor can vary depending on the size and complexity of the project, as well as the region of the country. Typically, commercial roofing labor is more expensive than residential roofing labor due to the larger size of the roofs and the specialized materials and equipment required.

Commercial Roofing TPO

Commercial Roofing TPO (thermoplastic olefin) is a type of single-ply roofing membrane that is commonly used on commercial and industrial buildings. TPO roofing membranes are made from a synthetic rubber material that is heat-welded together to form a waterproof barrier on the roof. Some of the key features of TPO roofing include:

-

- Energy efficiency: TPO roofing reflects the sun’s rays, which can help to reduce energy costs for air conditioning in the building.

-

- Durability: TPO roofing is resistant to punctures, tears, and UV rays, making it a long-lasting option for commercial roofs.

-

- Flexibility: TPO roofing can expand and contract with temperature changes, which helps to prevent cracking and splitting.

-

- Environmentally friendly: TPO roofing is made from synthetic materials, which can be more eco-friendly than traditional roofing materials such as asphalt.

TPO commercial roofing is typically installed using a heat-welding process, which involves welding the seams between the roofing sheets to create a watertight barrier. This installation process is typically performed by professional roofing contractors and requires specialized equipment.

Commercial roofing products like Flute filler is a material that is used to fill the flutes or corrugations of metal roofing systems. The flutes are the raised, parallel ridges that run perpendicular to the roof’s slope. These flutes provide structural support and stability to the metal roofing, but can also create thermal bridges that can cause heat loss in the winter and heat gain in the summer.

Flute filler is used to fill these flutes and create a more energy-efficient roof. There are different types of flute fillers, but most are made of insulation materials such as polystyrene or polyurethane. These materials are lightweight and easy to install, and can help to improve the energy efficiency of the roof.

Flute filler can also be used to improve the acoustical performance of metal roofing systems by reducing the amount of noise that enters the building.

Flute filler is typically installed by professional roofing contractors, who will first clean and prime the surface of the roof before applying the filler to the flutes. This can be done by injecting the filler into the flutes, or by gluing the filler to the roof surface.

Commercial Roofing PVC

Commercial Roofing PVC (polyvinyl chloride) is a type of single-ply roofing membrane that is commonly used on commercial and industrial buildings. PVC roofing membranes are made from a plastic material that is heat-welded together to form a waterproof barrier on the roof. Some of the key features of PVC roofing include:

-

- Durability: PVC roofing is known for its excellent resistance to chemicals, fire and UV rays, making it a long-lasting option for commercial roofs.

-

- Flexibility: PVC roofing can expand and contract with temperature changes, which helps to prevent cracking and splitting.

-

- Energy efficiency: PVC roofing reflects the sun’s rays, which can help to reduce energy costs for air conditioning in the building.

-

- Environmentally friendly: PVC roofing is made from synthetic materials, which can be more eco-friendly than traditional roofing materials such as asphalt.

Commercial Roofing & Industrial PVC roofing is typically installed using a heat-welding process, which involves welding the seams between the roofing sheets to create a watertight barrier. This installation process is typically performed by professional roofing contractors and requires specialized equipment. PVC roofing systems are known for their durability and longevity, often have a lifespan of 20-30 years with proper installation and maintenance.

Commercial Roofing EPDM

What is the most common commercial roofing material? Commercial Roofing & Industrial EPDM (ethylene propylene diene monomer) is a type of single-ply rubber roofing membrane that is commonly used on commercial and industrial buildings. EPDM roofing is made from a synthetic rubber material that is adhered or mechanically fastened to the roof deck to form a waterproof barrier. Some of the key features of EPDM roofing include:

-

- Durability: EPDM roofing is known for its excellent resistance to UV rays, ozone, and extreme temperatures, making it a long-lasting option for commercial roofs.

-

- Flexibility: EPDM roofing can expand and contract with temperature changes, which helps to prevent cracking and splitting.

-

- Easy to repair: EPDM roofing can be easily repaired using patches or roofing adhesive.

-

- Environmentally friendly: EPDM roofing is made from synthetic rubber and does not require the use of asphalt or heat during installation.

Commercial Roofing EPDM roofing is typically installed using one of two methods: ballasted or fully adhered. In a ballasted installation, the EPDM membrane is laid over the roof deck and held in place by large stones or pavers. In a fully adhered installation, the EPDM membrane is glued to the roof deck using a special adhesive. This installation process is typically performed by professional roofing contractors and requires specialized equipment. EPDM roofing systems are known for their durability and longevity, often have a lifespan of 20-30 years with proper installation and maintenance.

Polyiso insulation is a type of insulation that is made from polyisocyanurate foam. It is commonly used in commercial and industrial roofing systems to improve energy efficiency and thermal performance. Some of the key features of polyiso insulation include:

-

- High R-value: Polyiso insulation has a high R-value, which is a measure of its ability to resist heat flow. This means that it is an effective insulation material that can help to reduce energy costs.

-

- Lightweight: Polyiso insulation is lightweight, making it easy to handle and install.

-

- Durable: Polyiso insulation is resistant to moisture, mold and mildew, and it can withstand extreme temperatures.

-

- Versatile: Polyiso insulation can be used in both roof and wall applications, and it can be installed as a continuous insulation layer.

Polyiso insulation is typically installed by professional Commercial Roofing contractors, who will place it between the roof deck and the roofing membrane. It can also be used in combination with other types of insulation, such as fiberglass or mineral wool, to improve the overall thermal performance of the roof.

Polyiso insulation is often used in roofing because of its high R-value per inch, durability, and its ability to withstand harsh weather conditions. It is also an eco-friendly insulation option because it is made from a closed-cell foam that does not absorb moisture and does not require the use of ozone-depleting blowing agents.

Commercial Corrugated Metal Roofing

A metal roof is a type of roofing system that is commonly used on commercial and industrial buildings. Metal roofs are made from a variety of materials, including steel, aluminum, copper, and zinc. Some of the key features of commercial metal roofs include:

-

- Durability: Metal roofs are known for their long lifespan and resistance to extreme weather conditions, such as high winds, heavy rain, and snow.

-

- Energy efficiency: Metal roofs reflect the sun’s rays, which can help to reduce energy costs for air conditioning in the building.

-

- Lightweight: Metal roofs are lightweight and easy to install, which can help to reduce labor costs.

-

- Recyclable: Most metal roofs are made from recyclable materials, making them an environmentally friendly option.

Commercial Roofing metal can come in different styles and designs, such as standing seam, corrugated, and interlocking metal shingles. Each type has its own advantages and disadvantages, such as standing seam metal roofs are known for their durability, while interlocking shingles are more suitable for steep-sloped roofs.

Commercial metal roofing systems are typically installed by professional roofing contractors, who will first remove the old roofing material and then install the new metal roof. The installation process can include attaching the metal panels to the roof deck using fasteners or adhesives, and sealing the edges and seams with a specialized sealant.

Commercial Roofing Metal roofs are a popular choice for commercial buildings due to their durability, low maintenance, and energy efficiency. They can also come with a variety of color options and finish options, which can help to enhance the aesthetic of the building.

Corrugated metal roofs are a type of commercial roofing metal roofs that are made from sheets of metal that have been formed into a series of corrugations or waves. These corrugations provide structural support and stability to the metal roofing, but can also create thermal bridges that can cause heat loss in the winter and heat gain in the summer.

Pros of Corrugated Metal Roofs:

-

- Durability: Corrugated metal roofs are known for their long lifespan and resistance to extreme weather conditions, such as high winds, heavy rain, and snow.

-

- Low cost: Corrugated metal roofs are generally less expensive than other types of commercial roofing systems.

-

- Easy to install: Corrugated metal roofs are relatively simple to install, which can help to reduce labor costs.

-

- Recyclable: Corrugated metal roofs are made from recyclable materials, making them an environmentally friendly option.

Cons of Corrugated Metal Roofs:

-

- Noisier: Corrugated metal roofs can be noisy during rain or hail storms.

-

- Thermal bridging: The corrugations in the metal roofing can create thermal bridges that can cause heat loss in the winter and heat gain in the summer.

-

- No insulation: Corrugated metal roofs do not have insulation, so additional insulation will be required to improve the thermal performance of the roof.

-

- Limited design options: Corrugated metal roofs have a distinct look and may not be suitable for some buildings’ aesthetics.

In summary, Corrugated metal roofs are a cost-effective, durable and easy to install roofing option for commercial buildings, but they lack insulation and can be noisy during rain and hail storms and not suitable for certain aesthetic buildings.

Commercial standing seam roofs

Commercial standing seam roofs are a type of metal roofing system that are commonly used on commercial and industrial buildings. They are made from sheets of metal that have been formed into long, vertical panels that run parallel to the roof’s slope. The edges of these panels are folded over to create a raised seam that runs the length of the panel. The raised seams are then fastened to the roof deck, creating a watertight barrier.

Some of the key features of commercial standing seam roofs include:

-

- Durability: Standing seam roofs are known for their long lifespan and resistance to extreme weather conditions, such as high winds, heavy rain, and snow.

-

- Energy efficiency: Standing seam roofs reflect the sun’s rays, which can help to reduce energy costs for air conditioning in the building.

-

- Watertight: The raised seams of standing seam roofs create a watertight barrier that helps to prevent leaks.

-

- Customizable: Standing seam roofs can be customized to fit the unique design and aesthetic of a building.

-

- Low maintenance: Standing seam roofs require little maintenance, as the raised seams help to prevent water from getting behind the panels.

Commercial standing seam roofing systems are typically installed by professional roofing contractors, who will first remove the old roofing material and then install the new standing seam roof. The installation process can include attaching the metal panels to the roof deck using clips or adhesives, and sealing the edges and seams with a specialized sealant.

Standing seam roofs are a popular choice for commercial buildings due to their durability, low maintenance, and energy efficiency. They also have a sleek and modern look, which can enhance the aesthetic of the building.

Slate is a natural stone that has been used for centuries as a roofing material. It is known for its durability, longevity, and aesthetic appeal. Some of the key pros and cons of slate roofs include:

Pros:

-

- Durability: Slate roofs can last for more than 100 years, making them one of the most durable roofing options available.

-

- Natural beauty: Slate roofs have a natural, rustic beauty that can enhance the aesthetic of a building.

-

- Resistant to fire, rot, and insects: Slate is a natural stone that is resistant to fire, rot, and insects, making it a low-maintenance roofing option.

-

- Recyclable: Slate is a natural and sustainable roofing material that can be recycled at the end of its lifespan.

Cons:

-

- Cost: Slate roofs can be expensive to install and repair, as they require specialized tools and expertise.

-

- Heavyweight: Slate is a heavy material that requires a strong roof deck to support it, which can add to the cost of installation.

-

- Fragile: Slate is a brittle material that can crack or break if it is not handled properly during installation or repair.

-

- Limited availability: Slate is quarried in a few places in the world and can be difficult to obtain for some areas.

In summary, slate roofs are known for their durability, natural beauty, and resistance to fire, rot, and insects. However, they can be expensive to install and repair, heavy, fragile and hard to obtain. They are typically used in historic or high-end buildings, where the aesthetic appeal of the natural stone is desired.

What’s the difference between commercial and residential roofing? Commercial uses heavy duty materials that can also be applied to Residences. Often Residential roofs are cheaper roof systems than commercial roofing services. A residential roof contractor in Danville, Virginia is a professional who specializes in the installation, repair, and maintenance of roofs on residential buildings in Danville and the surrounding area. These contractors typically have experience working with a variety of roofing materials, such as asphalt shingles, metal, tile, and slate. They should also be licensed, insured and have a good reputation.

When looking for a residential roof contractor in Danville, Virginia, it is recommended to ask for references and check their reputation, ask for proof of insurance and licenses, ask for a detailed estimate, and ask about their warranty policy. It is also a good idea to get multiple estimates from different contractors to compare prices and services.

Some reputable residential roof contractors in Danville, Virginia include: Dickens & Sons Construction, Moss Home Improvements, AS Pugh, Skywalker Roofing, Cenvar Roofing, Rempfer Roofing, All Phase Roofing, Big Lick Roofing, Modern Day Roofing, Artisan Roofing, Perimeter Roofing and Exteriors, Gary’s Roofing, Gupton Sheet Metal, Gupton Roofing, Jones building Systems, New South Metals, Anthony Hall Roofing, Roofing Solutions, Service Roofing and Sheet Metal, Dillon Roofing, Valdez Family Roofing.

It’s important to note that this is not an exhaustive list and it is always good to do your own research and check the reviews and ratings of the companies before hiring one. Verify your contractor is in good standing by visiting: https://www.dpor.virginia.gov/LicenseLookup

Shelter Construction Services offers commercial roofing solutions. We Offer Financing on all Commercial & Residential Roofs